MESI SAWS & BLADES

About our company

Our company has over 40 years’ experience in offering customised industrial cutting solutions for the food industry. We have a team specialising in meeting the needs of all customers who have put their trust in our company. Working alongside suppliers, distributors, customers and other companies in the sector, our continuous R&D process strives to constantly improve the quality and efficiency of our bandsaws and bandknives. We use leading quality steel to manufacture our products, combined with high-precision machinery and technology to ensure results in accordance with requirements in the sector.Our production process

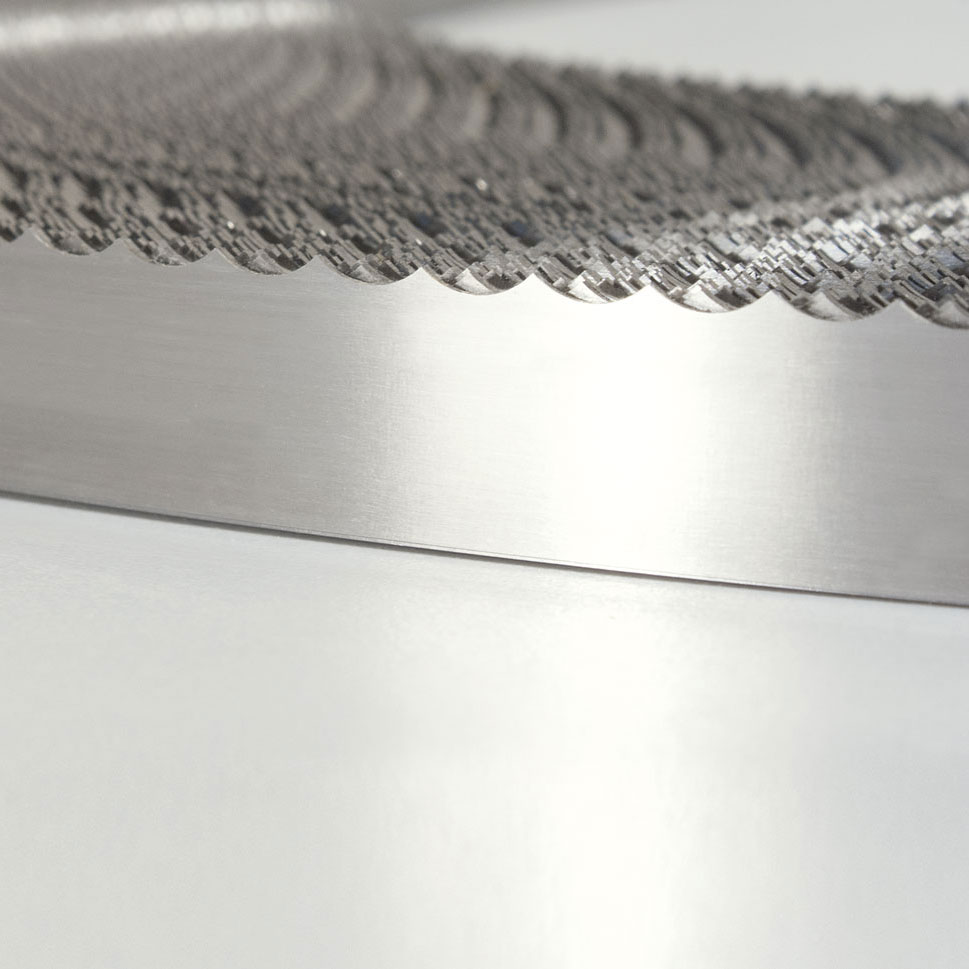

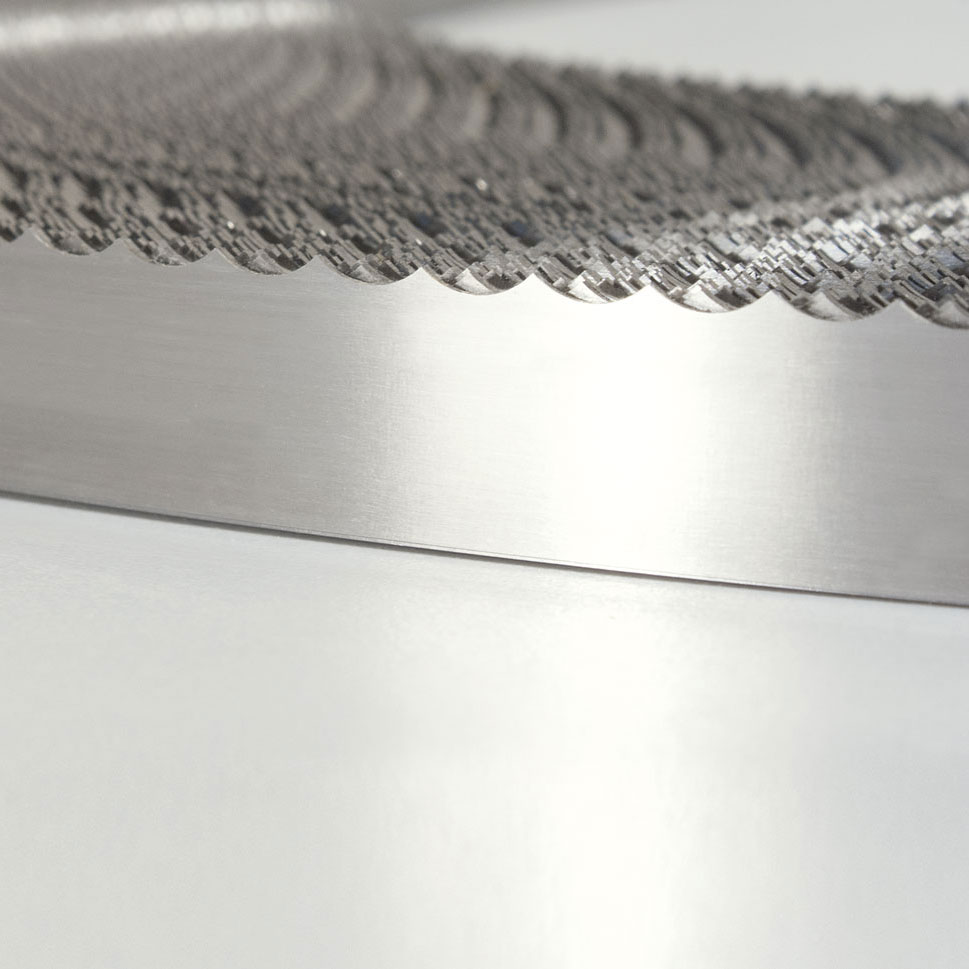

Grinding

The process to create the teeth. The teeth are made by high-precision grinders with repeatability to ensure identical tooth geometries throughout the process. This manufacturing process also avoids tensions in the steel structure, which reduce the saw’s working life.

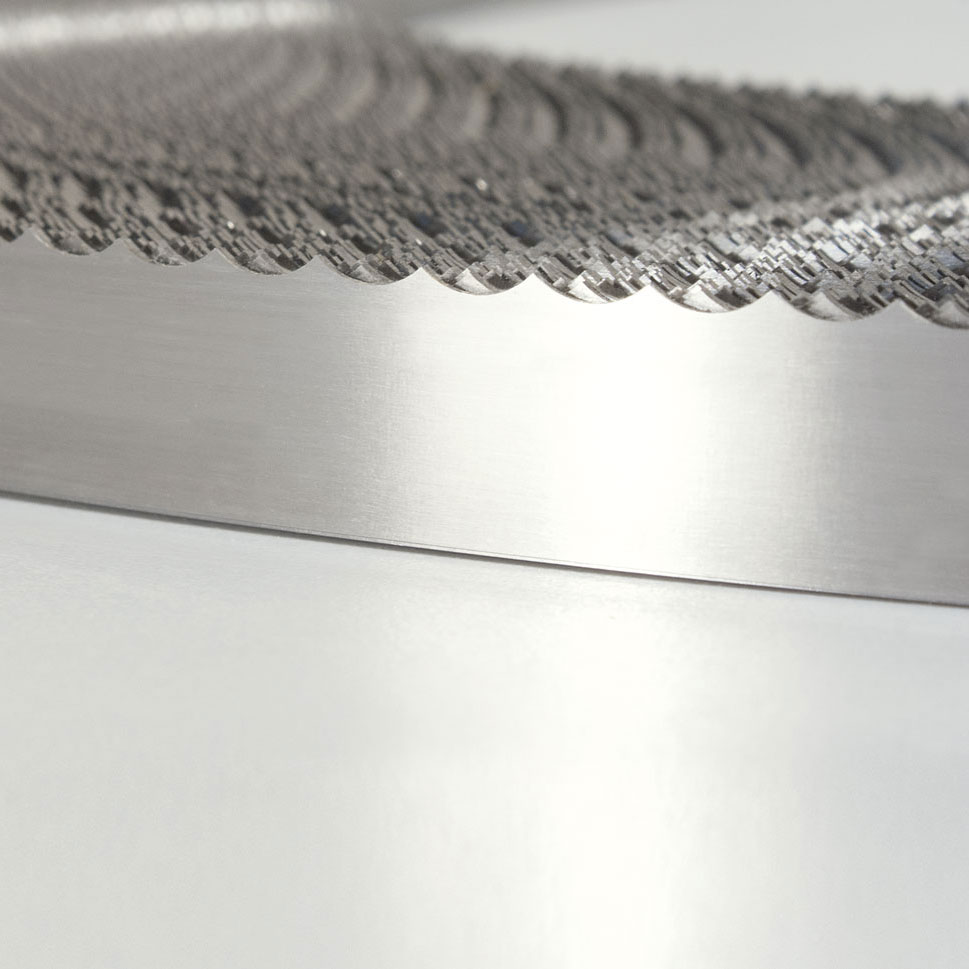

Setting

The process to set the direction of the teeth. Setting prevents the product from pressing laterally on the saw band, reducing friction. It also ensures improved cutting performance and a longer working life for the saw band. Three types of setting can be carried out: Low / Normal / High. This variation in setting achieves different performances and feed rates for the product. It can also mean cleaner cuts with less waste.

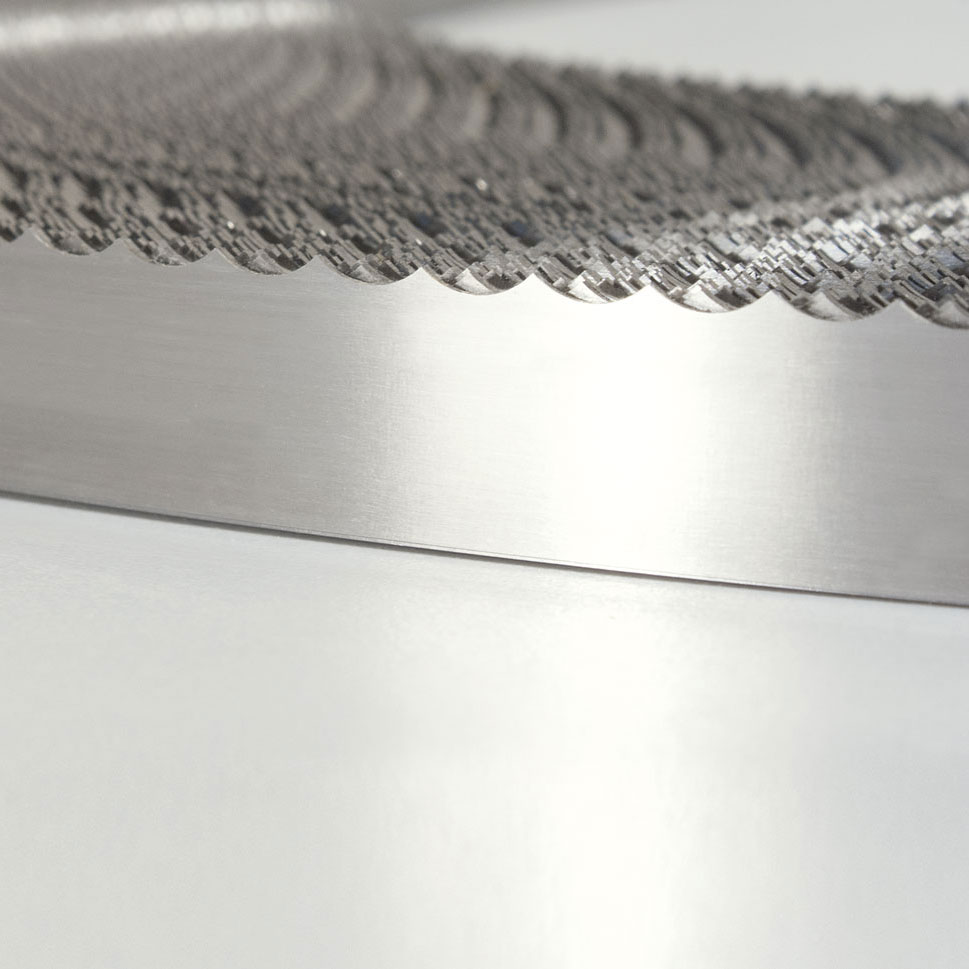

Hardening

The process by which greater hardness is achieved at the tip of the tooth, which is key to the saw band’s performance and working life. Hardening can also produce a bright rather than a black finish. This bright finish is suitable for cutting fish and cephalopods, where normal hardening may stain the fish.

Welding

This process is crucial in ensuring the saw bands perform correctly. The welds are produced in electronically controlled machines to achieve perfectly aligned high-strength welds. The quality of the welding process avoids vibrations and noise in the cutting equipment, which cause breakdowns and inconvenience to the user, as well as breakages in the joints and production stoppages due to changing the saw band.

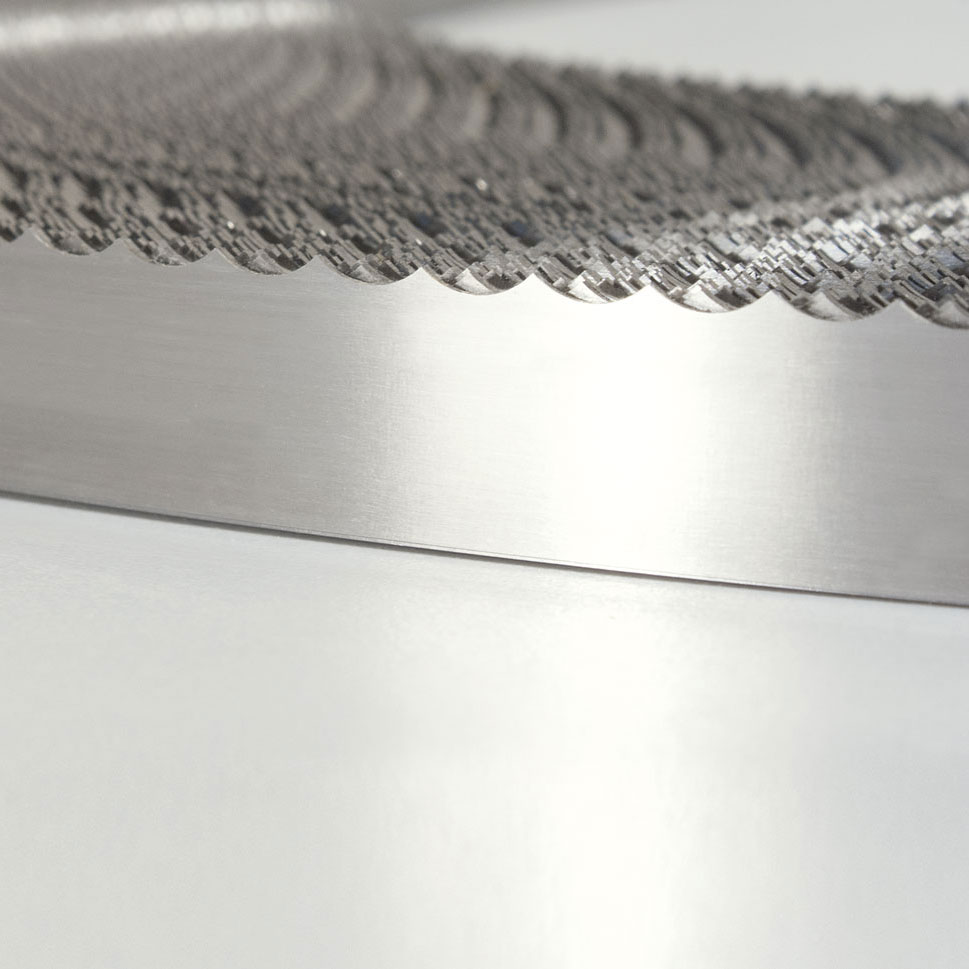

Tooth type and size

Tooth size is measured using two different systems: metric and imperial. The imperial system is most commonly used in food saws. Here tooth size is identified by the number of teeth per inch.nIn the metric system, on the other hand, tooth size is identified by the distance from the tip of one tooth to the next one (tooth pitch).Product packaging

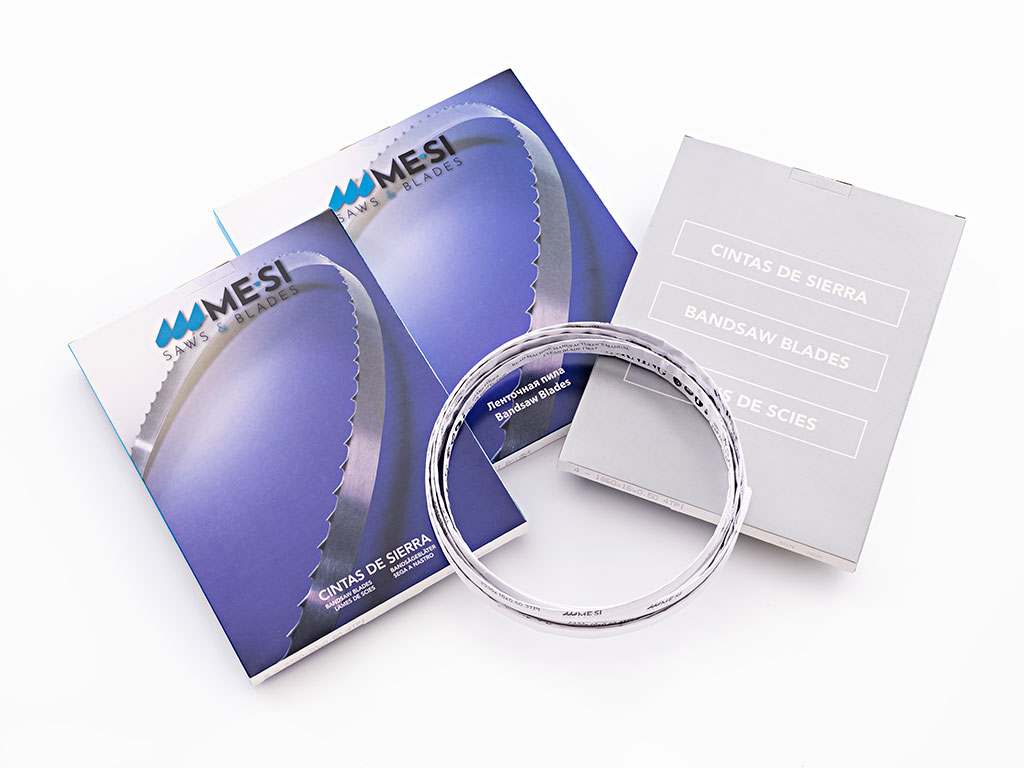

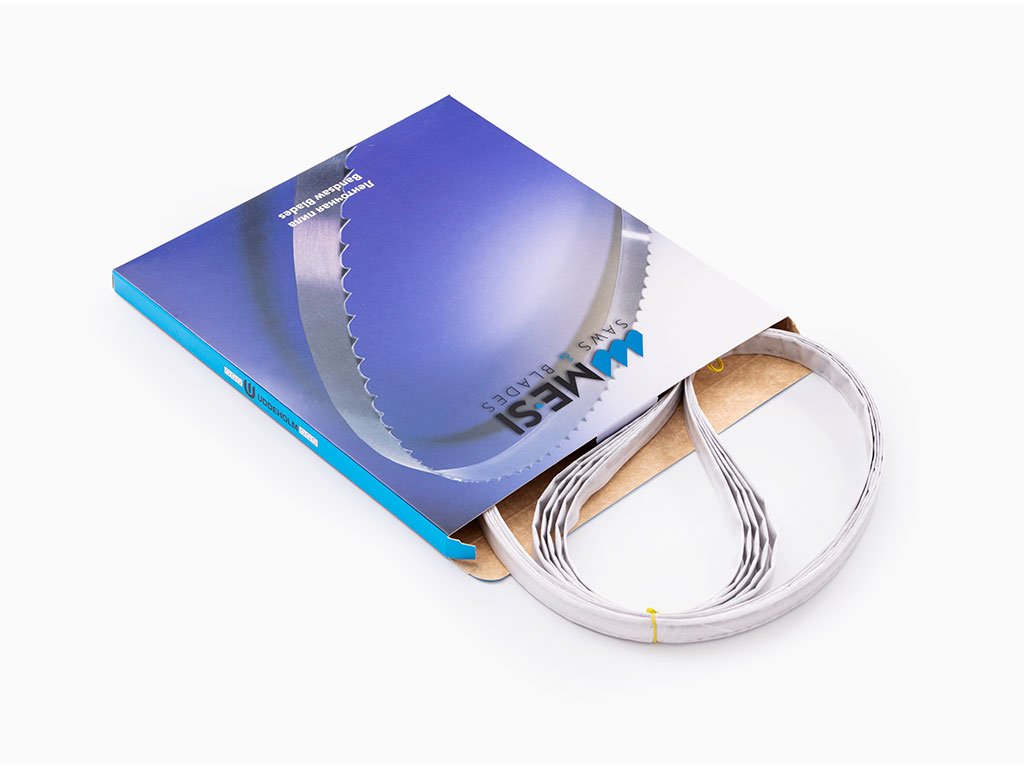

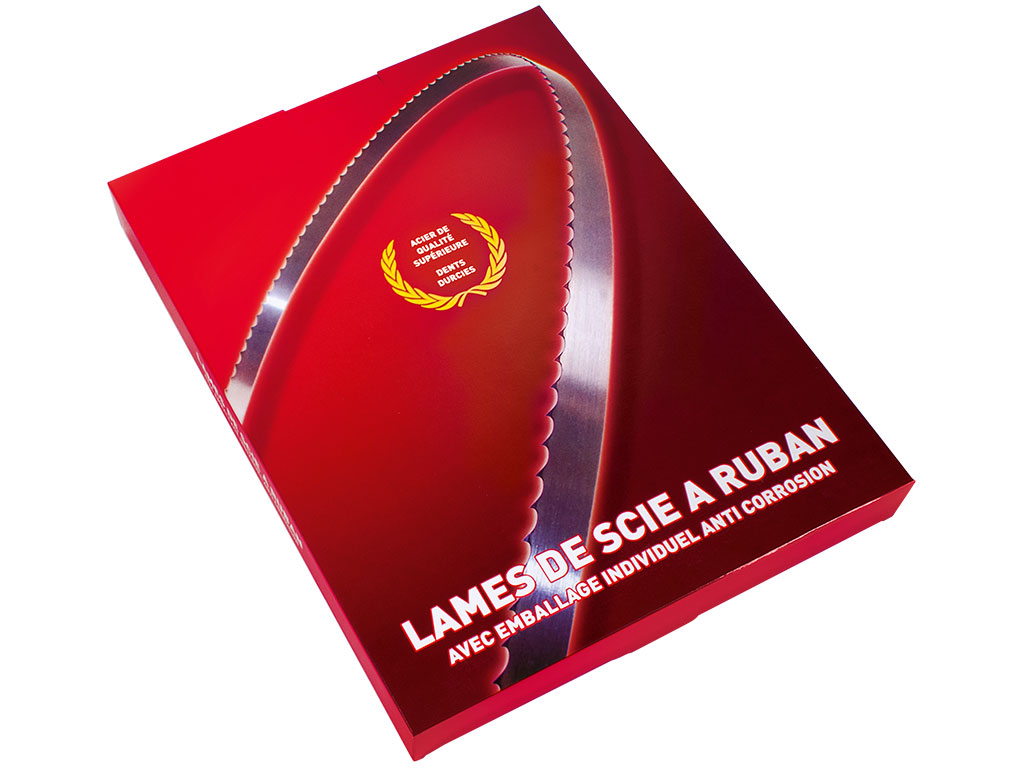

As part of our commitment to maximum quality and customer satisfaction, packaging is vitally important to ensure our products are preserved and arrive at their destination correctly. Our packaging systems for bandsaws and band rolls guarantee protection against bangs and dirt. We count on a wide range of packaging options:- Boxes with different designs and capacities.

- Individually wrapped in printed or blank paper.

- Individually wrapped in paper and boxed.

- Packed in plastic bags.

- Saw band coils are also available boxed or wrapped in protective paper. Option to manufacture coil length to order.